ITRI – Developing a solid-state electrolyte of Li-Batteries to the next generation

EARTO Innovation Awards 2021 – RTOs International Network (RIN)

It is known that conventional Li-batteries (LIBs) with organic liquid electrolytes have safety issues such as flammability and leakage. Gel electrolytes have been in the market for many years, but are mostly used in portable electronic devices, not yet in power LIBs. The main reason is that like polymers, gel electrolytes have lower ionic conductivity than liquid electrolytes, with difference by more than an order of magnitude. This limits the application of gel or polymer electrolytes in power LIBs. NAEPE (Networked Amide Epoxy Polymer Electrolyte) is a quasi-solid state, non-flammable and low-cost electrolyte with high ionic conductivity and high voltage stability. NAEPE is a key material for the next generation of solid-state Li-batteries and especially suitable for a variety of applications that operate at high voltage and temperature.

Improving the cyclability of cells at high voltages (4.5V) and temperatures (55℃)

Reducing 10 % electrolyte consumption and 4% cell cost and enhancing 3.5% energy density of cells

Reducing 10 % electrolyte consumption and 4% cell cost and enhancing 3.5% energy density of cells

Simplifying the manufacturing process of solid-state LIBs without the requirement of heating or UV light for polymerisation

NAEPE/ceramic solid-state electrolytes can be internally connected in series for 12V of LIBs, and reduces cells packaging costs and increases by 20% modules energy density

The next generation of solid-state Li-batteries

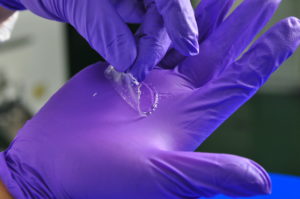

Non-flammable and low-cost NAEPE is an electrolyte material with high ionic conductivity and voltage stability, which can greatly improve the safety and cycle life of LIBs. NAEPE is achieved through the polymerization of liquid electrolytes with the addition of a cross-linking agent and an initiator at ambient temperatures. The state of the electrolyte depends on the extent of the polymerization and can be controlled by the amount of the cross-linking agent (i.e. Amide Epoxy Oligomer, AEO) added. When the AEO amount is below 5%, the electrolyte behaves like a gel, and when superior to 5 wt%, a significant cross-linking reaction occurs and the electrolyte becomes a quasi-solid. NAEPE can also be blended with inorganic ceramic electrolyte materials to form an organic/inorganic composite solid-state electrolyte that can replace not only the liquid electrolyte but also the separator.

High safety, low-cost and easy processing

NAEPE can be applied in LIBs for electric vehicles, energy storage systems, and mobile electronic devices. NAEPE has the following advantages that are confirmed by several cell manufacturers in Taiwan.

- High safety (non-flammable, leak- and impact- proof batteries)

- Low-cost and easy processing (AEO can polymerize at ambient temperatures to absorb liquid electrolytes)

- Excellent cyclability at high voltage (>4.5V) and temperature

- Multi-applications (from portable electronic devices to vehicles)

- Enhancing the energy density of cells by 3.5% (by saving usage of the electrolyte by 10 wt%)

New opportunities for electric vehicles

LIBs are the most common battery type in electric vehicles, and their amounts are growing drastically over the recent years. The goal of ITRI is to increase the cycle life and recycling efficiency of LIBs. NAEPE technology can provide not only a long cycle life, but also an easy recycling process to collect high value metal elements (Co, Ni, Cu) of the LIBs. NAEPE is a non-toxic and non-flammable material that improves the safety and the efficiency of the composition breakdown of LIBs. The quasi-solid-state electrolyte of NAEPE is suitable for large format batteries (25Ah~40Ah) evaluated by cell manufacturers, and saves many containers of materials where 18650 or 21700 cylindrical cells are wasted.

The Industrial Technology Research Institute (ITRI) is a leading research and technology organisation with more than 6,000 outstanding researchers. Its mission is to drive industrial development, create economic value, and enhance societal well-being through technology R&D. Founded in 1973, it pioneered in IC development and continues to nurture emerging tech ventures and deliver its R&D results to industries.

© Photos Credit: ITRI

< Previous Next >